Copper Alloy Tubes For Heat Exchangers . Carbon steel, stainless steel, and higher alloys are slightly less efficient, but all perform similarly. copper alloy tubes have been used for heat exchangers for over 100 years being specified in the british admiralty in 1870. an aluminum fin and a stainless steel tube can help improve and maximize cooling efficiency in the cooling industry. based on thermal modeling comparisons using htri software, copper and copper/nickel are typically the most conductive material available for exchanger tubes. the copper alliance refined several useful design principles for coils made with smaller diameter copper tubes. 24 rows copper tubes for heat exchangers are characterised by excellent heat conduction and corrosion resistance properties.

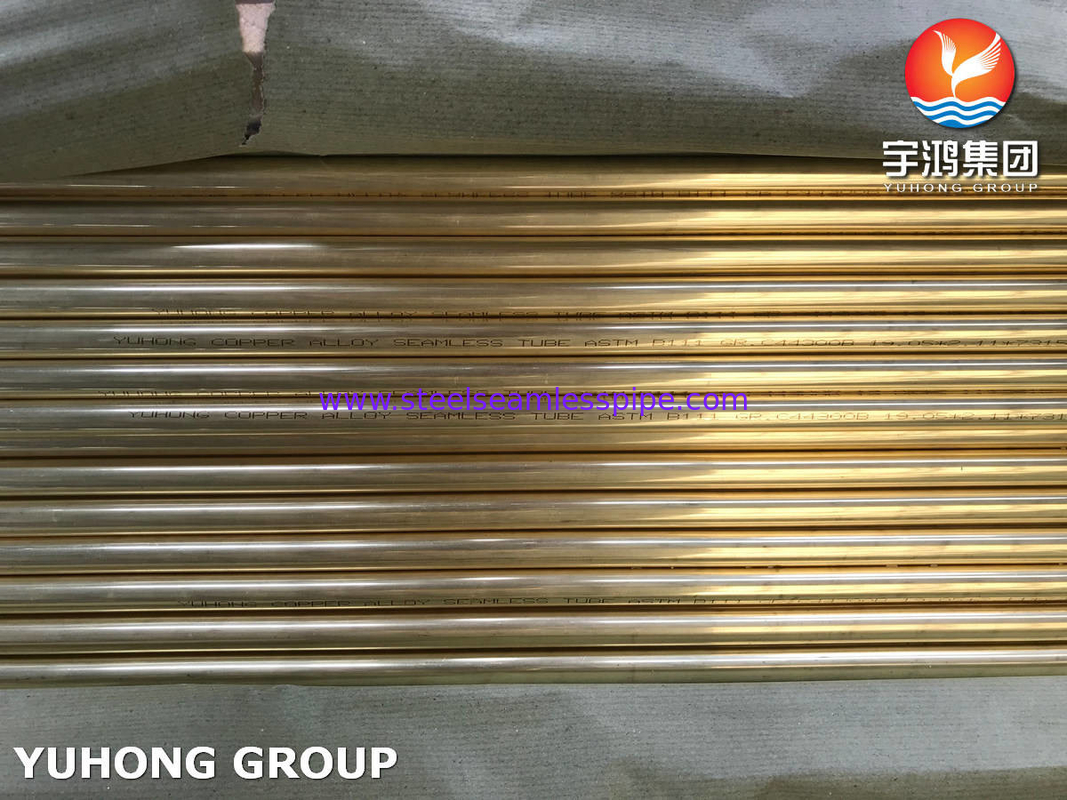

from www.steelseamlesspipe.com

copper alloy tubes have been used for heat exchangers for over 100 years being specified in the british admiralty in 1870. 24 rows copper tubes for heat exchangers are characterised by excellent heat conduction and corrosion resistance properties. the copper alliance refined several useful design principles for coils made with smaller diameter copper tubes. based on thermal modeling comparisons using htri software, copper and copper/nickel are typically the most conductive material available for exchanger tubes. an aluminum fin and a stainless steel tube can help improve and maximize cooling efficiency in the cooling industry. Carbon steel, stainless steel, and higher alloys are slightly less efficient, but all perform similarly.

ASTM B111 C44300 Copper Alloy Steel Seamless Tube Heat Exchanger Tube

Copper Alloy Tubes For Heat Exchangers based on thermal modeling comparisons using htri software, copper and copper/nickel are typically the most conductive material available for exchanger tubes. based on thermal modeling comparisons using htri software, copper and copper/nickel are typically the most conductive material available for exchanger tubes. the copper alliance refined several useful design principles for coils made with smaller diameter copper tubes. an aluminum fin and a stainless steel tube can help improve and maximize cooling efficiency in the cooling industry. copper alloy tubes have been used for heat exchangers for over 100 years being specified in the british admiralty in 1870. 24 rows copper tubes for heat exchangers are characterised by excellent heat conduction and corrosion resistance properties. Carbon steel, stainless steel, and higher alloys are slightly less efficient, but all perform similarly.

From tubingchina.com

ASTM B395 C28000 C44300 C68700 C70600 C71500 U Bend Copper Alloy Heat Copper Alloy Tubes For Heat Exchangers based on thermal modeling comparisons using htri software, copper and copper/nickel are typically the most conductive material available for exchanger tubes. the copper alliance refined several useful design principles for coils made with smaller diameter copper tubes. an aluminum fin and a stainless steel tube can help improve and maximize cooling efficiency in the cooling industry. . Copper Alloy Tubes For Heat Exchangers.

From www.steelseamlesspipe.com

ASTM B111 C44300 2.0470 Copper Alloy Seamless Tube Heat Exchangers Copper Alloy Tubes For Heat Exchangers an aluminum fin and a stainless steel tube can help improve and maximize cooling efficiency in the cooling industry. based on thermal modeling comparisons using htri software, copper and copper/nickel are typically the most conductive material available for exchanger tubes. Carbon steel, stainless steel, and higher alloys are slightly less efficient, but all perform similarly. the copper. Copper Alloy Tubes For Heat Exchangers.

From www.neximalloys.com

Copper Tubes for Heat Exchangers & Nexim Alloys Copper Alloy Tubes For Heat Exchangers 24 rows copper tubes for heat exchangers are characterised by excellent heat conduction and corrosion resistance properties. the copper alliance refined several useful design principles for coils made with smaller diameter copper tubes. an aluminum fin and a stainless steel tube can help improve and maximize cooling efficiency in the cooling industry. copper alloy tubes have. Copper Alloy Tubes For Heat Exchangers.

From www.steelseamlesspipe.com

ASTM B111 C44300 Copper Alloy Steel Seamless Tube Heat Exchanger Tube Copper Alloy Tubes For Heat Exchangers copper alloy tubes have been used for heat exchangers for over 100 years being specified in the british admiralty in 1870. Carbon steel, stainless steel, and higher alloys are slightly less efficient, but all perform similarly. based on thermal modeling comparisons using htri software, copper and copper/nickel are typically the most conductive material available for exchanger tubes. . Copper Alloy Tubes For Heat Exchangers.

From dwdbrass.com

Copper Alloy Tube for Heat Exchanger Brass Tubes, Copper Pipes Copper Alloy Tubes For Heat Exchangers 24 rows copper tubes for heat exchangers are characterised by excellent heat conduction and corrosion resistance properties. based on thermal modeling comparisons using htri software, copper and copper/nickel are typically the most conductive material available for exchanger tubes. the copper alliance refined several useful design principles for coils made with smaller diameter copper tubes. copper alloy. Copper Alloy Tubes For Heat Exchangers.

From neximalloys.com

Cupro Nickel Tubes 95/5, 90/10 & 70/30 Heat Exchangers & Condensers Copper Alloy Tubes For Heat Exchangers an aluminum fin and a stainless steel tube can help improve and maximize cooling efficiency in the cooling industry. based on thermal modeling comparisons using htri software, copper and copper/nickel are typically the most conductive material available for exchanger tubes. copper alloy tubes have been used for heat exchangers for over 100 years being specified in the. Copper Alloy Tubes For Heat Exchangers.

From www.steelseamlesspipe.com

ASTM B111 C70600O61 Copper Nickel Alloy Low Finned Tube For Heat Copper Alloy Tubes For Heat Exchangers Carbon steel, stainless steel, and higher alloys are slightly less efficient, but all perform similarly. the copper alliance refined several useful design principles for coils made with smaller diameter copper tubes. copper alloy tubes have been used for heat exchangers for over 100 years being specified in the british admiralty in 1870. based on thermal modeling comparisons. Copper Alloy Tubes For Heat Exchangers.

From www.alibaba.com

Thick Walled 70/ 30 Copper Alloy Nickel Tube For Heat Exchanger Buy Copper Alloy Tubes For Heat Exchangers Carbon steel, stainless steel, and higher alloys are slightly less efficient, but all perform similarly. the copper alliance refined several useful design principles for coils made with smaller diameter copper tubes. 24 rows copper tubes for heat exchangers are characterised by excellent heat conduction and corrosion resistance properties. an aluminum fin and a stainless steel tube can. Copper Alloy Tubes For Heat Exchangers.

From ezsteel.en.made-in-china.com

DIN17660 Cuzn20al2 F39 Smls Copper Alloy Tube Heat Exchanger Round Pipe Copper Alloy Tubes For Heat Exchangers copper alloy tubes have been used for heat exchangers for over 100 years being specified in the british admiralty in 1870. the copper alliance refined several useful design principles for coils made with smaller diameter copper tubes. an aluminum fin and a stainless steel tube can help improve and maximize cooling efficiency in the cooling industry. . Copper Alloy Tubes For Heat Exchangers.

From www.nachi.org

Copper Tube Heat Exchanger Inspection Gallery InterNACHI® Copper Alloy Tubes For Heat Exchangers an aluminum fin and a stainless steel tube can help improve and maximize cooling efficiency in the cooling industry. based on thermal modeling comparisons using htri software, copper and copper/nickel are typically the most conductive material available for exchanger tubes. 24 rows copper tubes for heat exchangers are characterised by excellent heat conduction and corrosion resistance properties.. Copper Alloy Tubes For Heat Exchangers.

From www.steelseamlesspipe.com

Astm B111 O61 Copper Alloy Tube C44300 C68700 Brass Tube For Heat Exchanger Copper Alloy Tubes For Heat Exchangers Carbon steel, stainless steel, and higher alloys are slightly less efficient, but all perform similarly. an aluminum fin and a stainless steel tube can help improve and maximize cooling efficiency in the cooling industry. copper alloy tubes have been used for heat exchangers for over 100 years being specified in the british admiralty in 1870. based on. Copper Alloy Tubes For Heat Exchangers.

From www.steelseamlesspipe.com

ASTM B111 / ASME SB111 C44300 Copper Alloy Tube Heat Exchanger Tube Copper Alloy Tubes For Heat Exchangers copper alloy tubes have been used for heat exchangers for over 100 years being specified in the british admiralty in 1870. 24 rows copper tubes for heat exchangers are characterised by excellent heat conduction and corrosion resistance properties. an aluminum fin and a stainless steel tube can help improve and maximize cooling efficiency in the cooling industry.. Copper Alloy Tubes For Heat Exchangers.

From www.mehtatubes.com

Copper Tubes, Copper Tubes for Heat Exchanger & Condensers, Copper Copper Alloy Tubes For Heat Exchangers copper alloy tubes have been used for heat exchangers for over 100 years being specified in the british admiralty in 1870. the copper alliance refined several useful design principles for coils made with smaller diameter copper tubes. Carbon steel, stainless steel, and higher alloys are slightly less efficient, but all perform similarly. based on thermal modeling comparisons. Copper Alloy Tubes For Heat Exchangers.

From www.munotmetalloys.com

copper tube for heat exchangers & at low price Copper Alloy Tubes For Heat Exchangers copper alloy tubes have been used for heat exchangers for over 100 years being specified in the british admiralty in 1870. an aluminum fin and a stainless steel tube can help improve and maximize cooling efficiency in the cooling industry. Carbon steel, stainless steel, and higher alloys are slightly less efficient, but all perform similarly. the copper. Copper Alloy Tubes For Heat Exchangers.

From www.indiamart.com

MFE Copper & its Alloys Heat Exchanger Corrugated Tubes, Water, Size 9 Copper Alloy Tubes For Heat Exchangers an aluminum fin and a stainless steel tube can help improve and maximize cooling efficiency in the cooling industry. Carbon steel, stainless steel, and higher alloys are slightly less efficient, but all perform similarly. copper alloy tubes have been used for heat exchangers for over 100 years being specified in the british admiralty in 1870. based on. Copper Alloy Tubes For Heat Exchangers.

From ezsteel.en.made-in-china.com

ASTM C71500 Copper Alloy Conderser Tube, Heat Exchanger Tube/Alloy Pipe Copper Alloy Tubes For Heat Exchangers copper alloy tubes have been used for heat exchangers for over 100 years being specified in the british admiralty in 1870. based on thermal modeling comparisons using htri software, copper and copper/nickel are typically the most conductive material available for exchanger tubes. 24 rows copper tubes for heat exchangers are characterised by excellent heat conduction and corrosion. Copper Alloy Tubes For Heat Exchangers.

From www.precision-steeltube.com

Copper Alloy TORICH ASTM B111 2mm Heat Exchanger Tubes Copper Alloy Tubes For Heat Exchangers copper alloy tubes have been used for heat exchangers for over 100 years being specified in the british admiralty in 1870. Carbon steel, stainless steel, and higher alloys are slightly less efficient, but all perform similarly. an aluminum fin and a stainless steel tube can help improve and maximize cooling efficiency in the cooling industry. the copper. Copper Alloy Tubes For Heat Exchangers.

From www.metalalloyscorporation.com

Heat Exchanger Copper Tubes Heat Exchanger Copper Finned Tubes Copper Alloy Tubes For Heat Exchangers based on thermal modeling comparisons using htri software, copper and copper/nickel are typically the most conductive material available for exchanger tubes. 24 rows copper tubes for heat exchangers are characterised by excellent heat conduction and corrosion resistance properties. the copper alliance refined several useful design principles for coils made with smaller diameter copper tubes. Carbon steel, stainless. Copper Alloy Tubes For Heat Exchangers.